When labs ask me where to start to improve turnaround time, I consistently highlight three essential levers: smart routing, automation, and real-time visibility. But identifying these levers is just the starting point. The real value comes from knowing how and when to apply them effectively to streamline optical lab operations.

In my experience, delays rarely occur due to major disruptions but rather due to minor inefficiencies that gradually accumulate. Perhaps a tray waits unnecessarily long for inventory, a job mistakenly routes to an overloaded station, or a technician spends valuable minutes on manual data entry tasks. With the right strategies, labs can proactively manage these friction points.

In this blog, I’ll walk through the most effective strategies I’ve seen for helping labs reduce lead times and operate more efficiently without compromising quality.

See how the right optical Lab Management Software (LMS) can streamline your lab. Read the guide.

Optimize Lab Routing for Maximum Efficiency

Efficient lab routing isn’t merely about moving jobs faster; it’s about precision and consistency. The core of any streamlined operation involves ensuring each job follows the most logical path through production, minimizing unnecessary steps and idle time.

Smart routing also supports better staging visibility and proactive decision-making when production lines become congested. With dynamic routing capabilities, lab managers can quickly adjust to temporary changes, such as equipment downtime or workforce shifts, without causing production delays. These adjustments are essential to streamline optical lab operations without disruption.

Embrace Lab Task Automation

If there’s one mantra I’ve adopted throughout my career, it’s “Automate whenever possible.” Lab task automation of repetitive tasks like job entry, blank selection and rule-based processing frees staff to concentrate on high-value tasks such as quality assurance.

Automation also plays a critical role in reducing technician workload, allowing staff to focus on quality control and exception handling. The goal is not to replace people but to free them from repetitive tasks that software can handle faster and with fewer errors.

Thai Optical Group (TOG) automated its processes to the extent that manual reviews were needed for only 5% of its jobs, down from 20%, vastly improving productivity. This is a great example of how lab task automation can directly streamline optical lab operations.

Leverage Powerful Lab Management Systems

An advanced LMS is the backbone of operational excellence, seamlessly connecting machinery, people and processes. It empowers labs to establish precise rules for routing, job prioritization, pricing, and exception handling.

When a comprehensive LMS is in place, labs gain the ability to create detailed rules for nearly every step in production. This includes clear definitions for how jobs move through the lab, how they’re priced and how anomalies or delays are immediately flagged and resolved. By capturing and standardizing these processes, an LMS significantly reduces dependency on “tribal knowledge,” ensuring operational consistency even amid staff turnover or team expansion.

In many cases, utilizing rules and giving visual indications as well as proper flows to eliminate touching a job twice for the same process. The rule of thumb for any given area should be to touch it once. This principle encourages completing a task fully the first time to avoid rework and improve efficiency, another critical component to streamline optical lab operations.

Collier Optical, for example, transitioned to Innovations LMS to tackle persistent challenges such as data corruption and communication breakdowns between different systems. After adopting the new LMS, they reported significant improvements, including an impressive reduction in breakage rates to nearly zero, clearly demonstrating the benefits of implementing a robust, integrated lab management system.

Utilize Real-Time Data and Analytics

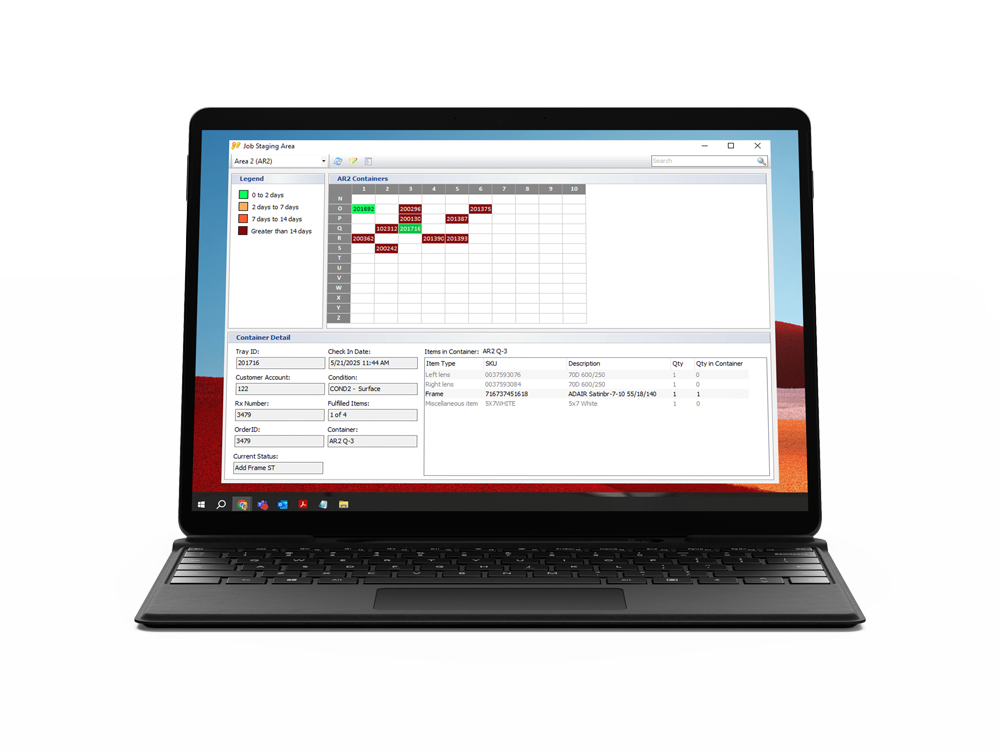

Streamline optical lab operations by building them on real-time visibility. Browser-based tools and job tracking modules give lab managers visibility into the status of each job, bottlenecks forming and areas that need attention most.

Interactive dashboards, job aging visualizations, and customizable reports turn raw data into actionable insights. By analyzing trends over time (like average job duration by department or peak downtime periods), labs can make data-backed decisions to improve turnaround further.

After adopting Innovations, Nippon Lenses achieved significant production improvements. They utilized real-time data tracking, resulting in defect rates dropping from 20% to just 7%.

Prioritize Integration Across Systems

System integration is often overlooked but can be a hidden source of delays and errors. When your LMS communicates seamlessly with lab equipment, EHRs, practice management systems (PMS) and ordering platforms, you eliminate the need for duplicate data entry and reduce the risk of transcription mistakes.

Integrated workflows also make it easier to provide real-time updates to ECPs and customers, increasing transparency and reducing the load on support teams. The fewer touchpoints a job has across disconnected systems, the faster and more reliably it moves. This reminds me of so many moments in the lab—those frantic, all-too-familiar scenarios that start with a simple phone call from a customer asking, “Can you check on my job?”

We’d politely ask them to hold, then the scramble would begin. Sometimes we’d head to the back to dig through stacks of trays or sift through the system to find any clue. Other times, we’d ask the customer for their name—then ask again when we couldn’t find anything—and then, awkwardly, ask for more details they probably didn’t even know, like which lab the job might’ve been farmed out to.

And when that didn’t work? We’d find ourselves roaming the lab, literally scanning trays for a name, hoping for a lucky break. Then came the real fun: once we found the job, we’d have to figure out why it was there, what stage it was stuck in, and most importantly, when it was going to be ready. It was a constant reminder of how much smoother things could be with better systems in place.

Continuous Improvement and Scalability

Streamlining is not a one-and-done initiative. As labs grow or shift focus, processes that once worked well may need refinement. A scalable LMS makes it easier to expand capacity, add new modules, and refine production logic without rethinking the entire operation.

Regular reviews of key metrics, such as breakage rates, throughput times, and equipment utilization, help labs identify new opportunities to improve. Labs that treat continuous improvement as part of their culture see the best long-term results.

I remember a time when we were reviewing some of our day-to-day processes, just trying to see where we could tighten things up. I asked a simple question about why a certain task was being done a particular way; nothing accusatory, just genuine curiosity. Without missing a beat, one of the staff members shrugged and said, “Well, we’ve always done it that way.”

That moment stuck with me. It wasn’t said with resistance, just habit. But it was a clear signal: we had a process running on autopilot, with no one really questioning if it was still the best approach. It was a turning point. We dug into that task and sure enough, there were better, faster and more accurate ways to handle it.

That experience taught me something valuable: whenever you hear, “We’ve always done it that way,” it’s not the end of the conversation; it’s the beginning of an investigation. That’s usually where improvement starts and another opportunity to streamline optical lab operations through smarter workflows, lab routing strategies, and ongoing lab task automation.

Empower Staff with Training and Tools

Technology alone won’t streamline your lab operations—people make it happen. That’s why investing in thorough training and equipping your staff with intuitive, effective tools is crucial. Clear dashboards, user-friendly interfaces, and well-documented processes help technicians and managers stay aligned and productive.

For example, when Nippon Lens implemented Innovations LMS, comprehensive staff training was key to a smooth transition from traditional manufacturing processes to fully digital lens production. As a result, employee confidence increased, directly improving productivity and efficiency throughout the lab.

Additionally, empowering your team involves creating an open feedback loop between frontline technicians and management. Often, the people closest to production have the clearest insight into everyday inefficiencies. With the right platform in place, their suggestions can quickly become actionable improvements, benefiting the entire workflow.

Wondering which LMS features matter most? Read our quick guide.

Conclusion: Achieving Operational Excellence

Applying these strategies (optimized lab routing, effective lab task automation, integrated systems, real-time analytics, continuous improvement, and staff empowerment) creates the ideal environment to streamline optical lab operations.

When built on a strong foundation of scalable technology and supported by knowledgeable staff, a lab can deliver faster, more accurate, and more consistent service without overextending its resources.

Whether you’re a small boutique lab or a high-volume facility, streamlining your operations is possible and worth the investment.